This week consisted of me testing the charging operations of the components. The goals of this week were to determine functionality and approximate charging time. The charging components are operational and able to charging a battery from 7.56 V to 8.10 V. Without any references, the state of charge of the battery via voltage readings could not be determined. Time was also immeasurable due to charger resets when input voltage was not within range. Testing of the components will continue next week with a recording device and longer duration in order to determine the maximum voltage.

Parts of the solar rack were dimension-ed and drawn in SolidWorks. After further thought, the solar rack will be redesigned as a single part instead an assembly.

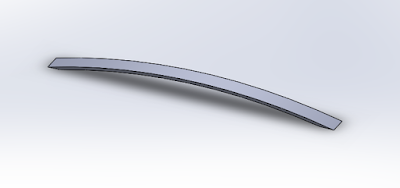

Solar racking rib

Aluminum bar to form rectangular base

Alan:

As stated above, this week was focus on making sure all the components work properly, that they are wired correctly, and testing the whole circuit in the sunlight. Both solar panels will be utilized because we need them to charge one battery pack each. I communicated with the Controls team to make sure which battery packs they will use and they decided to use the 4AA pack.

Two solar are going to be used because charging multiple batteries with one solar panel would not work well. It is possible to connect batteries in parallel in order for one solar panel to charge multiple battery packs but the issue with this is that all the batteries need to have the same voltage, otherwise the battery pack with highest voltage will discharge into the lower voltage one. This is not ideal because the battery packs will not always have the same voltage.

No comments:

Post a Comment